Types Of Measurement

DIFFERENTIAL MEASUREMENT

Where a tank is sealed and/or pressurised a differential measurement is used. There are two basic types :-

A) Dry leg DP or B) Wet leg DP

In both cases the construction of the sensor is somewhat different from that described earlier in that the process may be presented to both sides of the measurement cell.

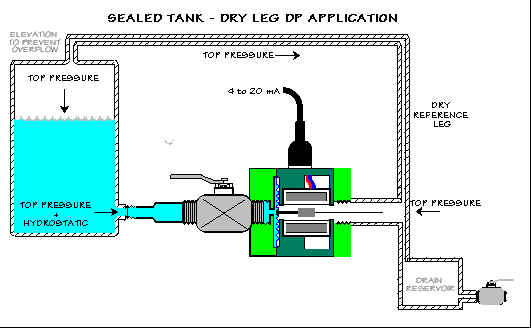

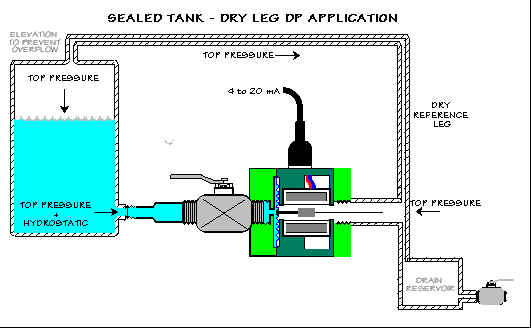

A) Dry leg DP

Transmitters used for this application are sometimes referred to as REFERENCE PORT. Effectively the hydrostatic pressure and top pressure are applied to one side of the measurement cell and top pressure only to the other side, thus cancelling its effect. The expression dry leg refers to the pressure line running between the top of the tank and the level sensor at the base, and the fact that it should remain dry or free of process fluid.

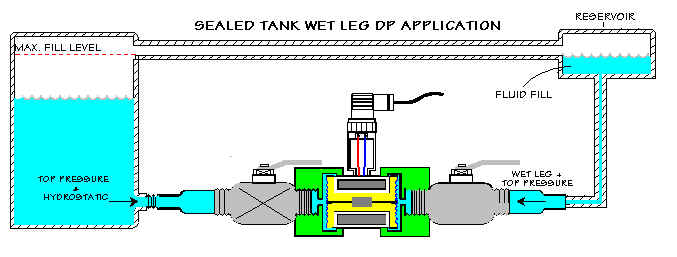

However, where the stored product is volatile and could introduce errors by entering and condensing in the reference leg during filling a "wet leg" is preferable.

B)

Wet Leg DP

B)

Wet Leg DP

In this case the reference leg is prefilled to known datum with fluid. The fluid may be either that being monitored, or in some cases, another compatable and imiscible liquid. In this case the signal is effectively reversed, i.e. with an empty tank maximum differential pressure exists and this drops away to zero when the tank is filled. The transmitter signal may be offset or reversed to suit the application requirements.

Often lagging or trace heating will be applied to the pressure impulse lines to maintain the desired wet or dry state.

Whilst supplying conventional externally mounted differential pressure sensors, PSM also offer a unique "internal wet leg" sensor assembly. This is easier to install (only one tank connection), cost effective (no external pipe-work) and ensures that the reference leg is automatically replenished each time the tank is filled. A version of this instrument has been successfully employed on the difficult shipboard application of seawater displaced fuel storage tanks. (See separate application note).