|

|

|

|

|

|

|

KEY FEATURES

|

|

|

|

Powerful, versatile, simple to apply & cost effective, attributes common to all members of PSMís new generation of Minders. Developing on the capabilities of its highly successful predecessor, the range offers comprehensive display & control facilities to keep you clearly in the picture. From a single tank installation, through a small tank farm, to a complete plant or ship wide network, the flexibility and connectivity offered by all units ensures that tailoring the optimum system for your particular application is straightforward & simple. Particular attention has been paid to engineering the products for installation under the harsh environmental conditions often found in Marine and Industrial applications. They are offered in a choice of formats, both panel and wall mount. The latter are of weatherproof epoxy coated steel construction suitable for outside installation, and with sufficient space for the termination of plant wiring. Each unit is normally provided with a display for local indication, and has both an RS485 serial port for network communications, and an RS232 port for host communications and local configuration |

|

|

|

Network

communication employs PSM’s own highly secure

protocol, whilst host communication is based on the

MODBUS protocol. This widely supported protocol enables

integration with systems from other manufacturers. To complete the picture PSM offer a comprehensive range of Hydrostatic and Ultrasonic Level transmitters, with particular variants having Marine “Type Approval” and being Intrinsically Safe certified. Also “TANKVIEW FOR WINDOWS” . is a cost effective PC based graphical monitoring package running under MS Windows 3.XX or 95/98 Operating system Please request separate data sheets covering transmitters & PC software.

|

||

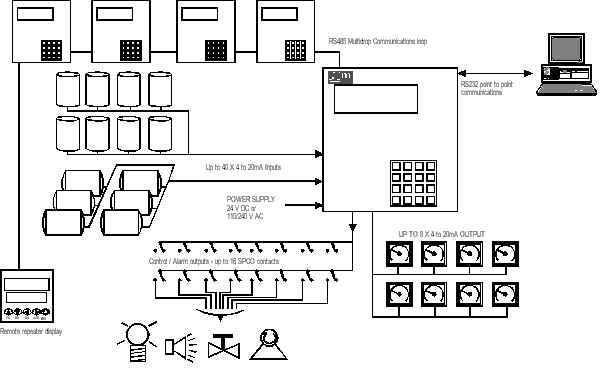

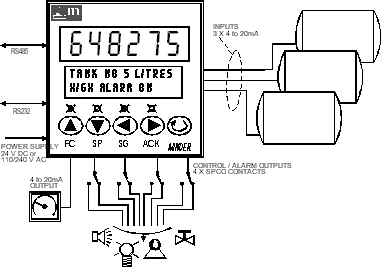

MODEL OPTIONS Single Tank Unit (STU) Providing full stand alone monitoring and control facilities for one vessel The unit has up to three 4 to 20 mA inputs for level, top pressure, and S.G. or temperature. Up to four control or alarm relay outputs, and a 4 to 20 mA retransmission (volume corrected) are also included. Triple Tank Unit (TTU) Employing the same Hardware as the STU this unit will monitor up to 3 vented tanks. Multi Tank Unit (MTU) The basic unit has 8 No. 4 to 20 mA inputs and 16 digital (volt free contact) inputs A further 32 4 to 20 mA inputs may be added, allowing up to 40 vented tanks to be monitored from one stand alone unit. An 8 channel 4 to 20 mA retransmission card, and a 16 relay (mains rated SPCO) may also be added to provide comprehensive local control facilities. Data Acquisition Module (DAM) In effect this is a "blind" version of the MTU intended for use where the display is required remote from the data collection point, for example in the control room. Input Display Module (IDM) This unit has no direct plant inputs or outputs, it communicates serially with other units to act as a remote or repeater display. All units have both RS 232 and RS485 serial communication ports. RS232 is used for local communication, for example to a Host Computer or for a Service Engineer to interrogate the unit. RS485 is used for the unit to unit communications network and may have a total cable run of up to 1.2 Km. Even this may be extended by the addition of low cost line drivers. |

SECURITY Ident No : A unique identifier for each unit which defines its position within a networked system Passwords : Access to system facilities is protected by a 2 level password system. Supervisor gains access to all facilities and Operator only to those that the Supervisor has allowed. Note :The comprehensive facilities of these instruments means that the foregoing only provides a brief overview of the main configuration parameters. Also, certain facilities are mutually exclusive |

HARDWARE SPECIFICATIONS STU & TTU

MTU

Note : The DAM has a similar mechanical packaging to the MTU but is not equipped with a display or keypad and has software facilities to support data acquisition only. PSM manufacture a complete range of Hydrostatic and Ultrasonic level transmitters, and will be pleased to discuss your particular requirements |